Laser engraving wood

At Laser Alliance, wood cutting and engraving are among our most requested services.

If you’re exploring work in other materials, visit our acrylic laser cutting or learn more about our acrylic laser engraving

For more information on our equipment capabilities, view our full laser cutting capabilities

If you’re ready to begin your wood laser engraving project, request a quote through our Quote Request”

We work with a wide range of wood species and provide high-precision laser cutting and engraving for everything from prototypes to custom signage and specialty products.

Laser Cutting Capabilities

Our industrial laser systems can cut wood cleanly and precisely in vector mode.

Cutting thickness: 0.020″ – 1″ thick

Maximum part size: 96″ x 48″

This makes our wood laser cutting ideal for large panels, furniture components, signs, and architectural elements.

Laser Engraving Capabilities

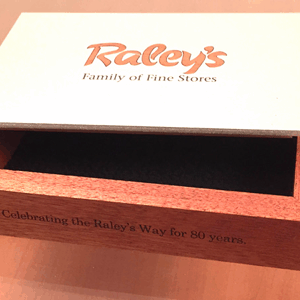

Laser engraving is a raster process, perfect for detailed graphics, text, serialization, artwork, branding, and personalization.

Standard engraving area: 39″ L x 24″ W and up to 11″ H.

Larger parts: Possible with additional alignments

We engrave hardwoods, softwoods, plywood, veneer, MDF, oak, maple, cherry, walnut, alder, poplar, and more—producing crisp details and consistent results.

Common Applications for Wood Laser Engraving

- Promotional products

- Exhibit and trade show displays

- Sign making

- Custom cabinetry

- Museum exhibit fabrication

- Architectural and ADA signage

- Inlays and decorative work

- Prototyping

- Personalized gifts and branded merchandise

Wood Laser Cutting & Engraving FAQ

Most engravings naturally appear in brown or dark brown tones, depending on the wood species.

For added customization, engraved areas can be filled with colored paints as a secondary process, creating strong visual contrast.

It depends on the finish and the final look you want.

If the wood will be painted:

Paint first – Ensure the paint is fully dry before engraving. We apply masking to protect the painted areas from smoke marks.

If the wood will be stained or varnished:

You have two options:

- Bare wood (no finish) – Best for minimizing burn residue.

- Pre-finished wood (thin coats) – Apply multiple thin coats for a smoother, professional finish.

Allow the finish to dry completely before engraving.

At Laser Alliance, we mask all surfaces to protect them from soot during engraving.

Yes. Wood should be fully painted and dried before engraving.

We apply a paper mask to the engraved zones to prevent smoke damage.

If your project requires color filling, we can keep the masking on the engraved areas upon request.

We minimize burn marks by masking the surface before engraving.

If removal is needed:

- Sanding – Use fine or medium-grit sandpaper (manual or sheet sander). Be cautious—over-sanding may affect engraving detail. Blow off dust before applying finish.

- Light scrubbing – Use a soft brush (e.g., toothbrush) with mild dish soap.

Scrub lightly only on affected areas.

Lighter woods provide better contrast.

Popular choices include:

- Alder

- Basswood

- Aspen

- Poplar

- Pine

- Hard Maple

- Cherry

- Walnut

Depending on your project: