Turn Your ideas into Reality

About us

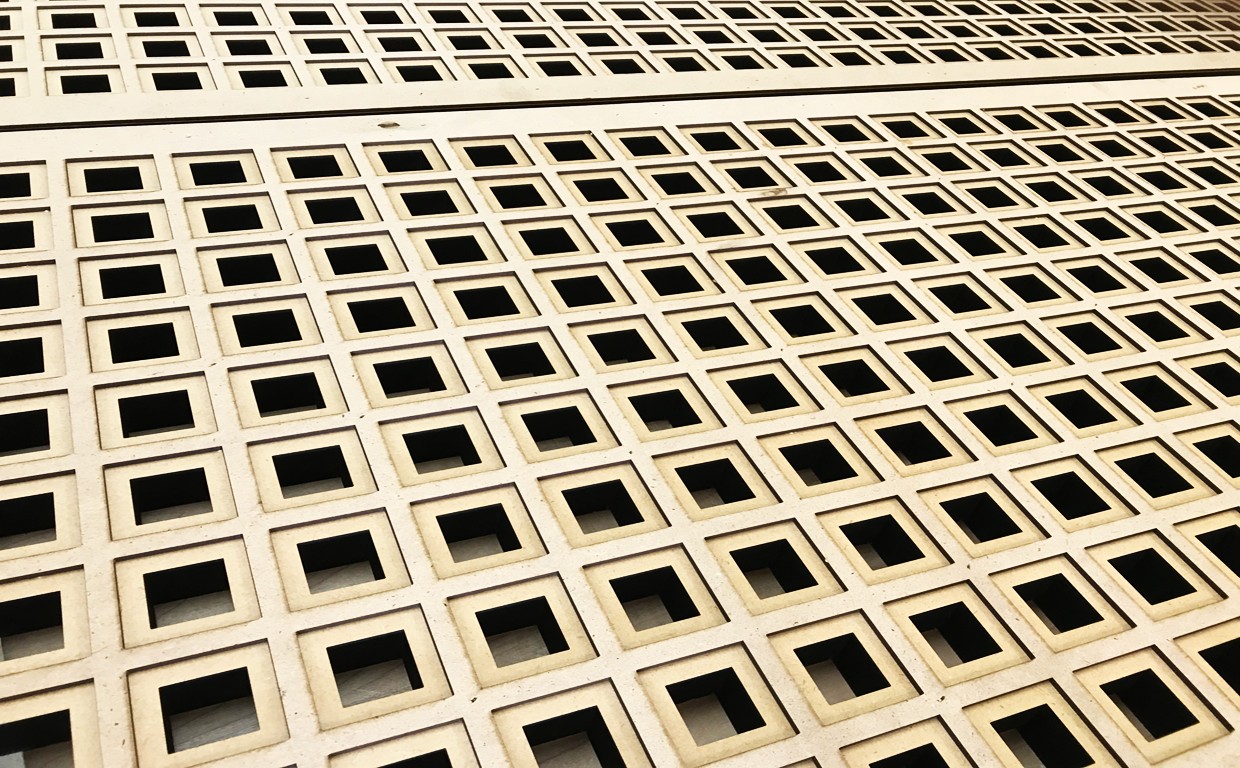

We specialize in visual graphic related products with intricate details that require high quality.

With a stream-lined process from start-to-finish and large inventory of materials, we can can complete your projects on time to meet your deadlines.

Laser Alliance LLC, located in Milpitas, California, is about 50 miles south of San Francisco and Oakland.

We use advanced CO2 industrial laser systems and are offering services to domestic and international clients across numerous industries.

We are looking forward to working with you on your next projects.

Our Clients

- High Tech

- Robotics

- Green Energy

- Bioscience

- Electronics

- Construction builders

- Educational institutions

- Exhibit trade show fabricators

- Sign makers

- Industrial designers

- Engineering projects and prototypes

- Manufacturing operations

Our Expertise

Logos, Stencils, Signs

Visual graphics related products

Displays, Puzzles, Letters, Maps

Promotional products

Doing business with Laser Alliance

Endless options

Choose from thousands of possible combinations of materials, thickness, colors and types. We can do both cutting and engraving in metals, plastics or woods and many others. So there is no need to outsource.

Convenience

We are centrally located in the SF Bay Area. Our location can be accessed by car within an hour from most Bay Area cities.

We offer services to all 50 states. Our main focus is northern California.Services

At Laser Alliance, we take care of each project from start to finish. Project details are handled with care and clear communication. Why deal with out of state, far-away laser shops where you are just a number.